Light Guide Plate Pattern Deisgn - Introducing BacklightFly

“BacklightFly is a Pattern Design & Output Software for Light Guide Plate of Backlight Modules”

Questions:

- Since Luminance is a function of density, how do you get correct Luminance without designing a real density distribution?

- If you actually design real density distribution and are unable to output same density result, how do you get correct Luminance?

- If the distribution of output pattern sizes is uncontrollable, how do you guarantee that your design will meet the process’s design rules?

- If the pitch is static, how do you avoid micro interactions (ex: Moiré Pattern)?

- Without precise design data, how do you gain from experience and systemize processes?

If you have same questions, stop doubting about yourself – let BacklightFly fulfills your ideas!

We’ve known that the density distribution of micro-patterns on light guide plates decides the performance of Luminance; therefore, the design of density distribution of patterns on light guide plates is the key to successful backlight modules manufacturing.

Printing process has its place for manufacturing light guide plates in the 80’ and 90’ and designers mostly used same-pitch and vary-shape size design (AKA same pitch design) to approach design density. As the processes advances, printing process is replaced gradually by chemical etching, physical etching and laser processes. The previous mentioned same pitch design is still widely used because of its ability to approach design density easily; however, the drawbacks that this method has brought along still remain challenges for light guide plate designers. For example:

- Pattern distribution has repeating patterns and often causes micro interactions (ex: Moiré Pattern).

- Unable to avoid either over-size patterns or tiny-size patterns at the same time.

- Over-size patterns (>200um): often causes light spots.

- Tiny-patterns: causing manufacturing challenges. Ex: Patterns under 50um often causes problems in etching process.

Same-size and vary-pitch design (AKA same size design) has gained its moments and become the mainstream; however, to output precise density and maintain good uniformity using this design still remains great challenges. Thus, designers use spline to control pitches and produce indirect density as their design density. The drawback of this method is obviously: density is not precise at all. Some designers use random method to produce precise density output and the result is quite good; unfortunately, the poor uniformity and the density discontinuous issue at the edges of density blocks make it unacceptable.

Because of the challenges, most designers are still unable to design with direct density and they use various methods to get the design density indirectly. And therefore, these designers need to maintain and develop a set of design rules for each process. The idea of using same design on all processes is still in the air and it also results consequences: early same pitch designs are not able to be converted to same size designs and creating a barrier on process advancing.

Yes, BacklightFly is developed and researched aims to resolve above issues. As you may have expected, we’ve already resolved these issues. Please allow us to represent you with our achievements:

Precise Output Density

Produce precise output which totally reflects your design.

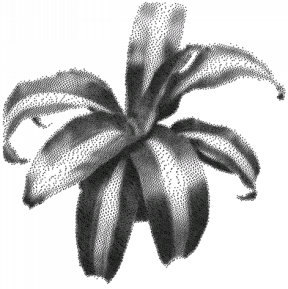

Image from Michael Balzer,University of Konstanz

|

Febees same size (process time ~2min)

|

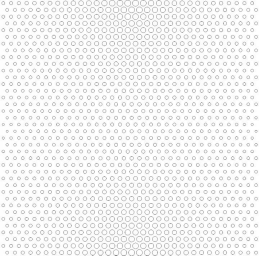

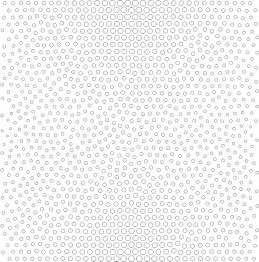

Same design file, multile output methods. All of our output methods can produce same output density results. One design file can satisfy all process and eliminating the desynchronize issue between Luminance and design file.

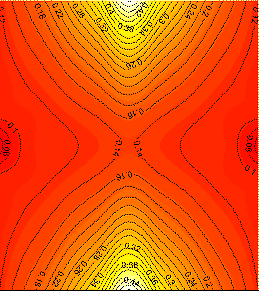

Density Distribution as Contour

|

Same pitch

|

Same pitch Fine grained

|

Same size Fine grained

|

Same size Regular

|

High Performance Design & Output

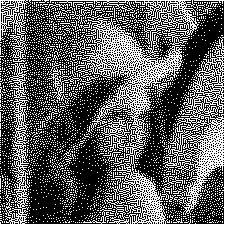

Independent system, does not rely on CADs, the design performance will not degrade with increasing plate size. Patterns output time is directly of pattern quantity. With our high precise density output capability, you can tell a good design with low resolution output and greatly reducing the design-output cycle. Once the design is final, just output with highest resolution – even a hundred million patterns can be outputted easily.

1 Bit TIFF output: 89DPI

|

1 Bit TIFF output: 254DPI

|