Backlight Design—BacklightFly Output

OutPut Principal of Light Guide Plate

email: support@febees.com

Abstract

After the completion of the design density, you must use the correct BacklgihtFly output, so that it can achieve the best result. This article will show you some explanations.

Preface

BacklightFly is using the same density of the design template regardless of same size or same pitch output, it ensures similar uniformity of the optical output, the main difference is the dispersion and taste, and you can use the same design draft, and compare the outputs.

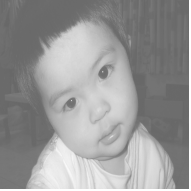

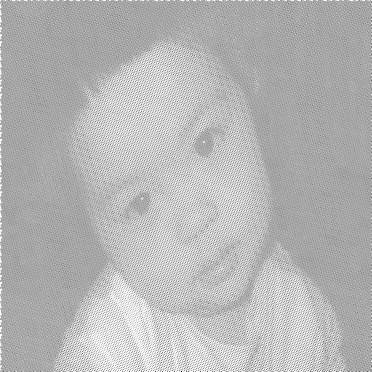

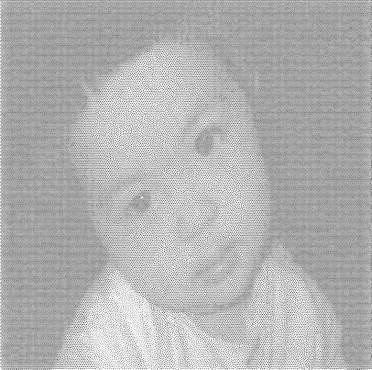

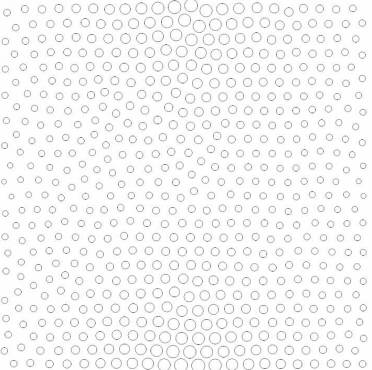

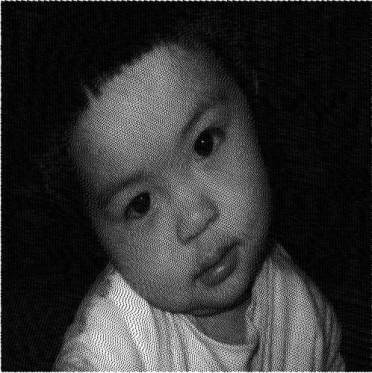

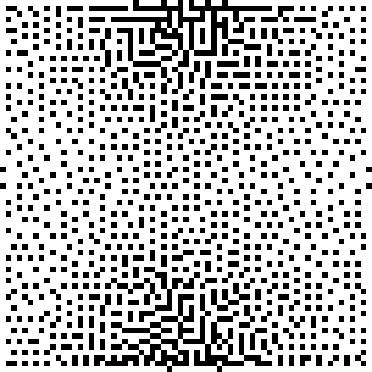

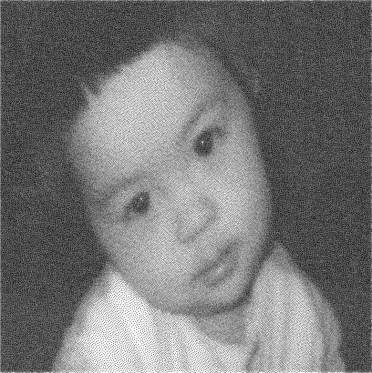

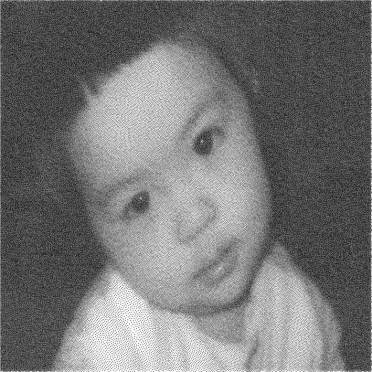

BacklightFly present in the real output point, the major offers five output modes. We use one photograph in Figure 1 and one density design in Figure 2 to show you the output examples:

|

|

Fig1 |

Fig2 |

- Same Pitch Output-->Regular

-

Same Pitch Output-->Fine Grained

- Same Size Output -->Regular

- Same Size Output -->Radonizatiom

- Same Size Output-->Fine Grained

Same Pitch Output-->Regular

With the same pitch output-->Regular

is the most traditional distribution method, using the fixed pitch, change the point size to meet the design density changes, this design density is the most uniform and easier to control. This generally used in the printing process, a few used in the etching process. Figure 3,4.

|

|

Fig3 |

Fig4 |

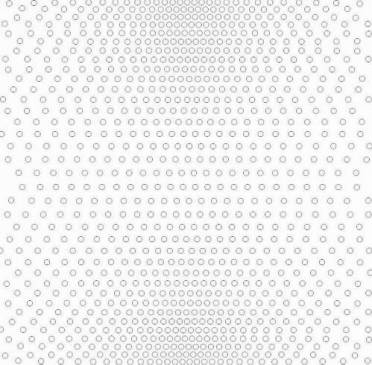

Same Pitch Output-->Fine Grained

Same Pitch Output-->Fine Grained output of the distribution is modified, using the best of rock and push the points to improve the rules of order problems caused by optical interference. Figure 5,6.

|

|

圖3 |

圖4 |

Same Size Output-->Regular

The same size output is a common design, especially popular in the laser process,two major types of the same size, one rule distribution arrangement, and the other is the random distribution of the order, We varied the pitch of dots in rule distribution arrangement, This output is high definition, some output pattern and real product shown in Figure 5,6.7.

|

|

Fig5 | Fig6 |

|

Fig7 mithras-optics Dr. Light LED nightlight |

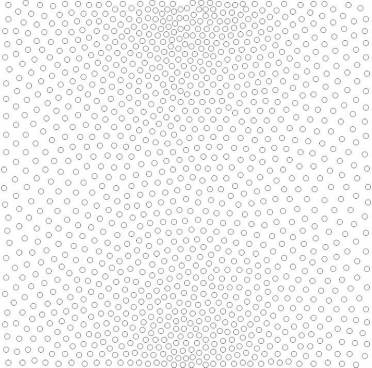

Same Size Output-->Rasterization

Same Size Output-->Rasterization output is mainly designed for laser machine which read TIFF format, this approach can easily solve large size can not preview too many points problems shown in Fig 10,11.

|

|

Fig 10 |

Fig 11 |

Same Size Output-->Fine Grained

This output is the most popular BacklightFly output, This output can be set the times of regression to achieve the optimized output,also can set the resolution to get best quality,you also can active the densest packing to gain over 78.5% of density, In order to save out processing time, you can choose low reolution for draft and high for final, low resolution shown in fig12,13,high resolution shown in fig14,15,densest packing shown in fig16,17

|

|

Low resolution Fig 12 | Low resolution Fig 13 |

|

|

High resolution Fig 14 | High resolution Fig 15 |

|

|

Deneset Packing Fig 16 | Deneset Packing Fig 17 |

Conclusion

Which output is better for the user to choose? BacklightFly recommend that in the printing process use the same pitch , if optical interference problem, you can turn on fine grained output option. To use the same size output must be considered the highest density, the minimum spacing is larger for printing, so the dots can not be too small or can not meet the design density, It is recommended to use the fine grained output and enable densest packing to overcome the problem of density. However, much of the low-density area may have a bright spot problem due to the printing point is larger, For others such as laser output, and fine grained output is the best method, In the uniformity adjustment period to deal with a low resolution to save the output time then finalized use the denset packing of high-resolution to get the best quality, if used in the graphics output, it is recommended to use high-resolution to achieve the best output image quality.

Looking for backlight design tool? BacklightFly is the best one!